The Problem

When DPL Group Ltd began work on a new MRI suite installation in Ipswich, they needed a specialist contractor to deliver the helium quench pipe system — a critical safety element of any MRI installation.

A helium quench pipe provides a safe escape route for helium gas in the unlikely event of a “quench,” where the MRI magnet suddenly loses its superconducting state. The liquid helium rapidly boils off and turns into helium gas. This expansion can create a sudden and extreme increase in pressure. Without a properly designed and installed quench system, helium gas can create dangerous conditions inside the MRI room. It’s a safety system that has to work.

As with many live hospital and healthcare environments, this project came with tight timelines, complex site restrictions, and the need to coordinate with multiple trades. DPL needed confidence that their chosen partner could handle the full design, manufacture, and installation while ensuring full compliance with Siemens’ technical requirements and hospital safety standards.

The Solution

ICE Ltd were appointed to provide a turnkey helium quench pipe solution — covering design, manufacture, testing, and installation.

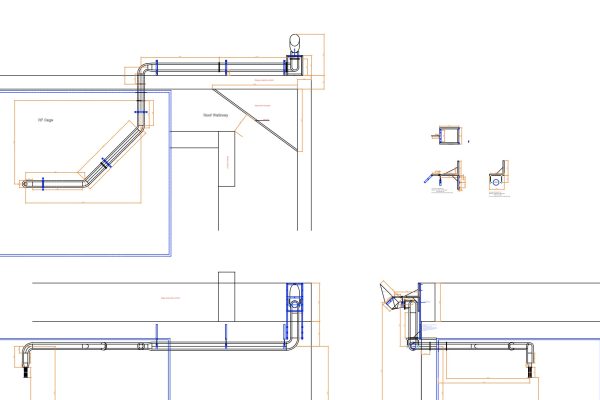

Our in-house engineering team began by reviewing the initial design and carrying out detailed pressure drop calculations and layout adjustments to suit the building’s specific layout, including a raised plant deck and several nearby windows and fire exits. All calculations and drawings were prepared and submitted for approval prior to fabrication, ensuring full compliance and manufacturer sign-off.

The system specification included:

- 200mm diameter, 3mm thick 304 stainless steel quench pipe

- Mild steel support brackets, painted for durability

- 50mm foil-backed insulation

- 1mm aluminium stucco cladding to protect external pipework

- Silicone rubber gaskets for airtight, flexible joints

The project was delivered in two phases to align with site activity, internal works were completed first, followed by the external sections once scaffolding was removed. Our installation team coordinated closely with site managers to keep disruption to a minimum and maintain progress across the wider MRI fit-out.

The Outcome

The quench pipe system was installed on time, fully tested, and approved by the MRI manufacturer.

DPL benefited from ICE’s end-to-end approach — one contractor handling design, calculations, manufacture, and installation — which removed friction, reduced project risk, and ensured total compliance.

The finished system provides a safe, reliable discharge route for helium gas, protecting patients, staff, and equipment while meeting all safety and performance standards.

By combining technical precision with practical, on-site experience, ICE once again delivered a seamless, fully compliant solution that allowed the main contractor to focus on the wider project delivery, confident that the MRI system was in expert hands.