The Problem

Our client a national pharmaceutical wholesaler was opening a new build, automated regional storage and distribution hub in the Wakefield Area.

The site required multiple chillstores designing and building to store and maintain pharmaceutical products within the MHRA guidelines of 2°C to 8°C.

Our scope of works was to build three new walk-in cold rooms, including all insulated walls, doors and ceilings within the new facility.

Within each of the three insulated enclosures it was required to design, supply and install refrigeration systems to provide a temperature-controlled environment of between 2°C and 8°C.

The temperature was to be maintained 24 hours per day, 365 days per year within the three enclosures.

It was a requirement for the new refrigeration systems to provide a fully flexible, 100% run and standby operation, with each system being capable of independently running room in the event of a failure.

LED lighting and emergency lighting was to be provided within the new chillstore.

There was a requirement for an alarm panel to record any system faults, door open alarms along with the temperatures within each of the rooms.

Once in operation all of the rooms where to be temperature mapped to ensure that the room temperature doesn’t to fall out of the specified parameters.

The Solution

ICE was awarded this Pharmaceutical Chillstore Project following a strict tender submittal, presentation and interview process.

Detailed heatload calculations were undertaken for the new enclosures based on the information supplied during the tender documentation and our equipment was selected based the results.

The project consisted of two parts the Main Chillstore and the Bulk Chillstore

The Main Chillstore enclosure was approx. 25.0m long x 8.0m wide, with a height of 3.50m.

Access to the pharmaceutical chillstore was via 4x 1.4m x 3.0m manual sliding doors.

Each door was fitted with a door switch that would alarm locally after a pre set and adjustable period of time of around 30 seconds of the door being left open.

To serve the Main Chillstore enclosure, we selected and installed FOUR independent, direct expansion refrigeration systems operating on R449A refrigerant, utilising fully housed packaged condensing units and ceiling mounted evaporator coolers.

The systems would run together in pairs, with each pair providing a total duty of 26.48kw under the conditions specified and each separate system capable of 13.24kw of refrigeration duty.

Each pair of systems would be capable of maintaining the desired room temperature in the event of a failure to one of the systems or whilst defrosting is taking place and would change over automatically either after a set period of one week or in the event of a fault.

The condensing units installed are Danfoss Optyma Plus packaged units, and the evaporator coolers are manufactured by Kelvion. Defrosting of the evaporators and drip trays is via electrical defrost heaters installed within the coolers.

The condensing units are positioned externally and are floor mounted.

The Bulk Chillstore enclosure was approx. 17.0m long x 9.0m wide, with a height of 11.0m. The enclosure was divided into two separate chillstores: The Storage Area and the Sorting Area.

Access to the pharmaceutical chillstore was via 3x 2.0m x 5.0m automated rapid rise doors along with a single personnel door.

Each door was fitted with a door switch that would alarm locally after a pre set and adjustable period of time of around 30 seconds of the door being left open.

To serve the Storage Area, we selected and installed FOUR independent, direct expansion refrigeration systems operating on R449A refrigerant, utilising fully housed packaged condensing units and ceiling mounted evaporator coolers.

To serve the chillstore, the systems would run together in pairs, with each pair providing a total duty of 25.90kw under the conditions specified and each separate system capable of 12.95kw of refrigeration duty.

Each pair of systems would be capable of maintaining the desired room temperature in the event of a failure to one of the systems or whilst defrosting is taking place and would change over automatically either after a set period of one week or in the event of a fault.

The condensing units installed are manufactured by Copeland, and the evaporator coolers are manufactured by Searle/Kelvion. Defrosting of the evaporators and drip trays is via electrical defrost heaters installed within the coolers.

To serve the Sorting Area, we selected and installed TWO independent, direct expansion refrigeration systems operating on R449A refrigerant, utilising fully housed packaged condensing units and ceiling mounted evaporator coolers.

Each installed system provides a total duty of 10.35kw under the conditions specified.

Each system would be capable of maintaining the desired room temperature in the event of a failure to the other or whilst defrosting is taking place and would change over automatically either after a set period of one week or in the event of a fault.

The condensing units installed are Danfoss Optyma Plus packaged units, and the evaporator coolers are manufactured by Kelvion. Defrosting of the evaporators and drip trays is via electrical defrost heaters installed within the coolers.

The condensing units for all systems are positioned externally and are floor mounted.

All refrigeration pipe work was supported using standard insulated pipe clamps.

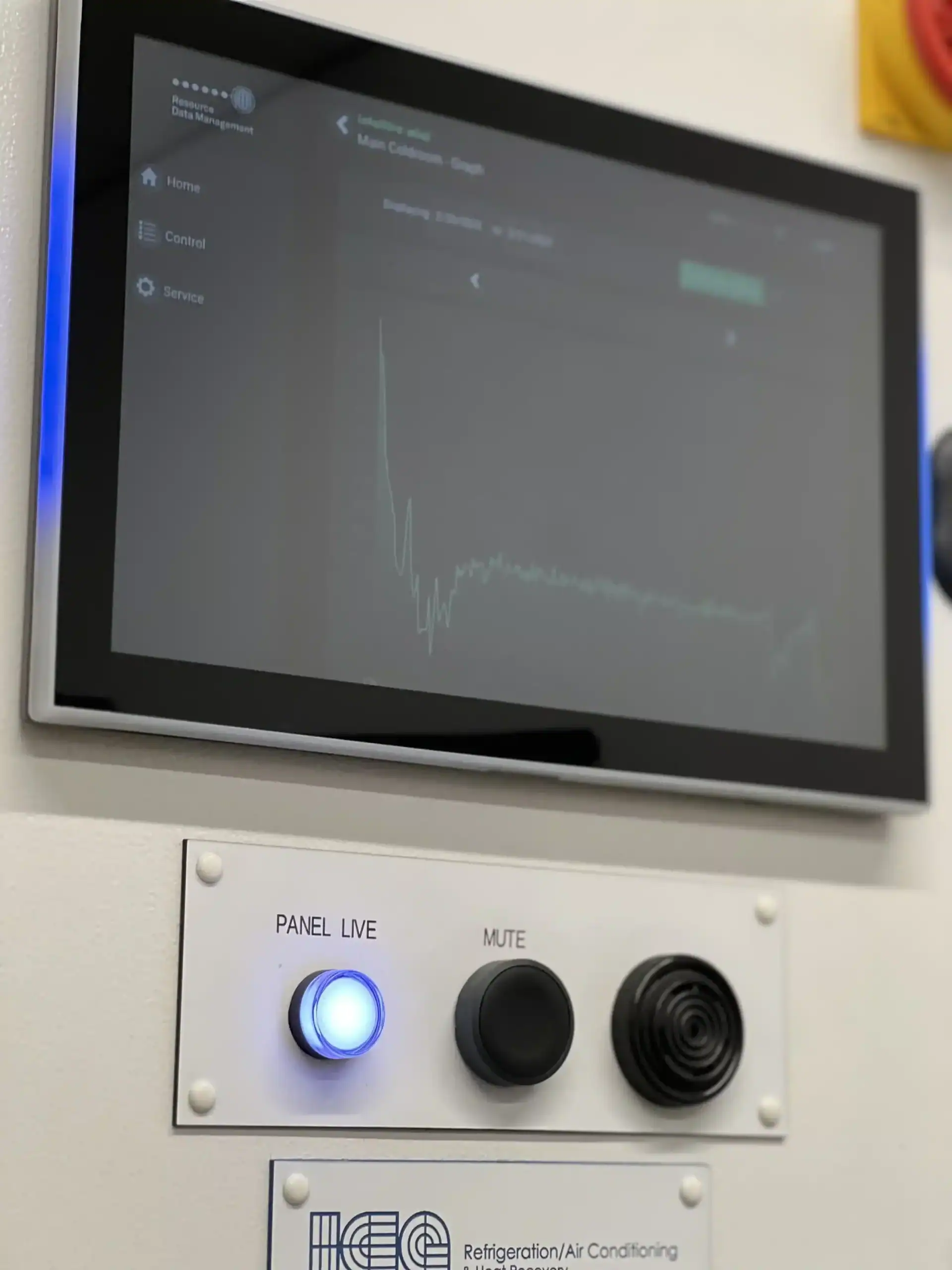

Alarm panels were installed for both enclosures housing an RDM controller that continually logs and records both temperatures and faults.

Energy efficient LED lighting was installed by our electrical contractors E and A Electrical Ltd and operated via a PIR sensor. Emergency lighting was also installed.

This project was designed and run by our Head of Projects Lee Hopkins and installed by our in-house installation team lead by our Project Manager Daniel Bush.

The Outcome

All installed systems within the pharmaceutical chillstores were installed to the highest of standards.

The project was handed over to the client in September 2023 with as built drawings, commissioning reports and O&M manuals.

All rooms were mapped and validated by the client and since commissioning have performed well and have stayed within the specified temperature limits of between 2°C and 8°C.