Nick Griffiths

10th October, 2022

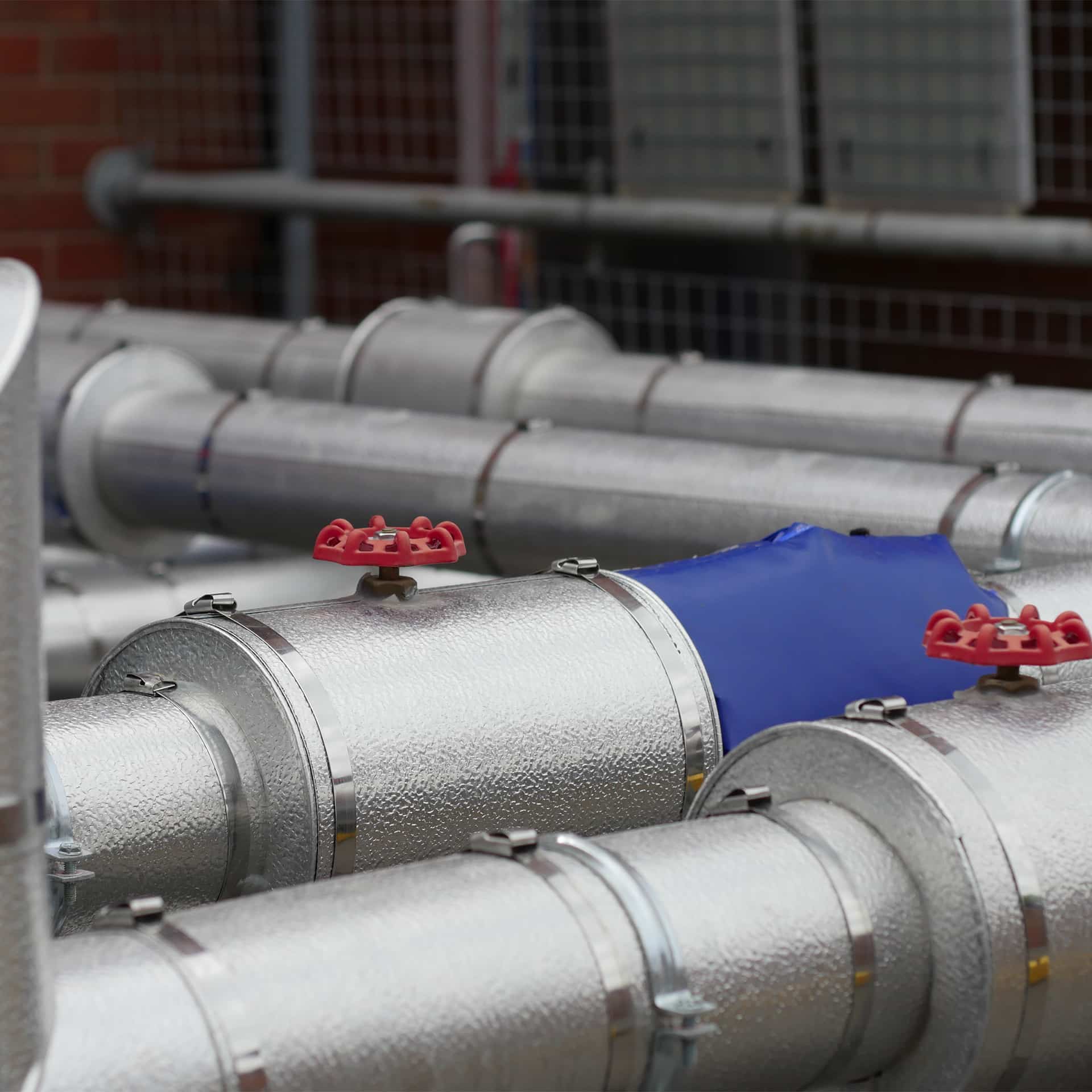

Are you chilled water system ready with winter approaching and ambient temperatures set to drop below freezing, now is a perfect time to get the glycol levels in your process cooling and chilled water systems checked.

When ambient temperatures drop below freezing point, any process cooling or chilled water pipework that is exposed to the elements is at risk. Inadequately protected systems may block, freeze, and burst, potentially causing thousands of pounds worth of damage, expensive repairs, and costly downtime in production.

If glycol and water solutions are not at the adequate levels, water can start to freeze and expand within the water circuit, causing pipework or heat exchangers to rupture. If water pipework ruptures, as well as expensive repair works to the chilled water system and loss of production due to downtime, it can cause flood damage to buildings, furnishings, stock, and equipment.

If a chillers heat exchanger bursts, then this can cause a leak between the water and refrigerant circuits, causing a total loss of refrigerant and flooding of the refrigeration circuit causing catastrophic damage. Water flooding a refrigeration circuit can result in a total write off of your chilled water system.

During maintenance checks on process cooling equipment, ICE Service Engineers take a small sample of the water from the system and using an onsite fluid analysis tool such as a refractor, measure the glycol levels concentration to give the solutions antifreeze level.

These checks are standard on Refrigeration Maintenance Plans for Process Cooling Equipment.

For more information please get in contact.