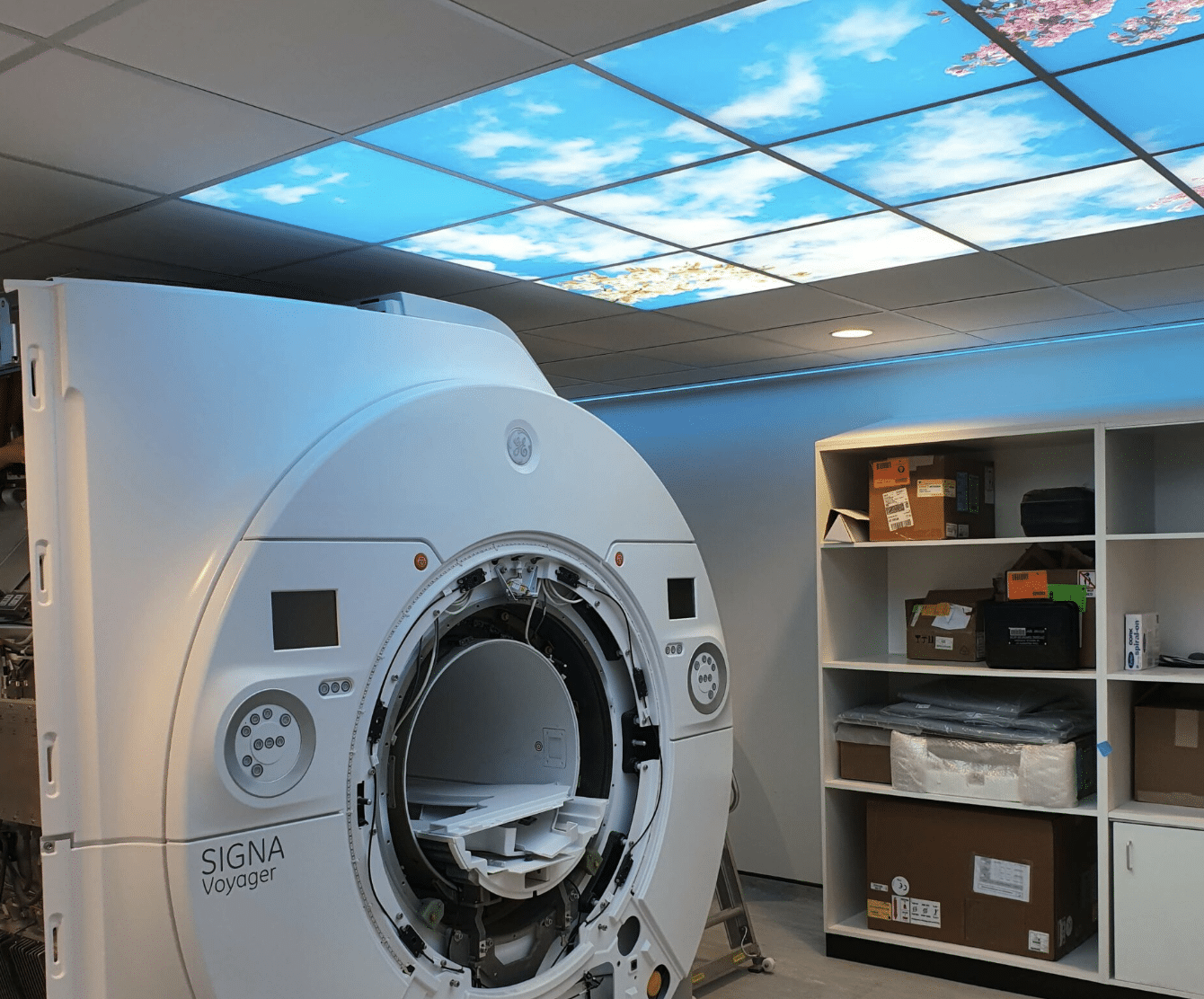

We Provide an emergency breakdown service 24 hours a day, seven days a week, 365 days a year.

Our Design and Projects team is backed by our Service and Maintenance department, providing maintenance contracts and F Gas compliance along with reactive breakdown assistance

24h Breakdown